JAN-WILLEM DEN OUDEN, LEAD GLOBAL DATA EXCHANGE, PORT OF ROTTERDAM AUTHORITY

'By joining forces, we connect parties and get the chain moving so that together we can achieve acceleration.'

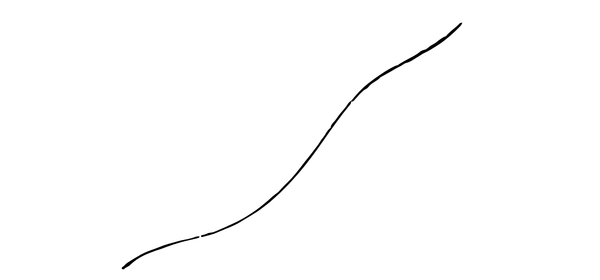

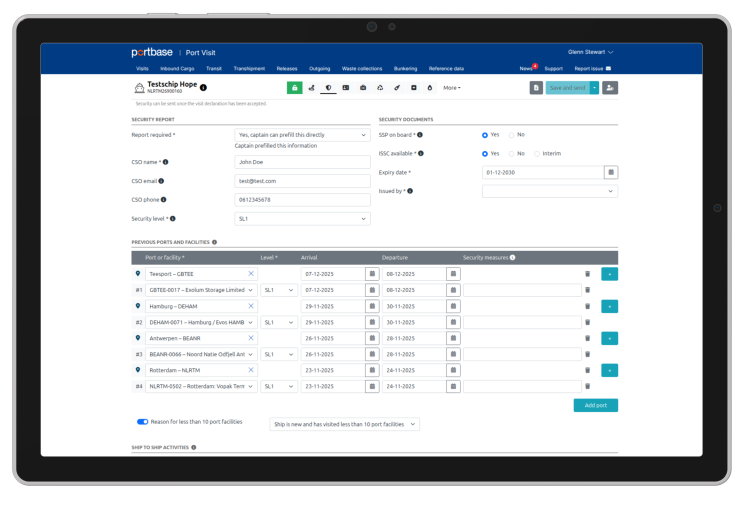

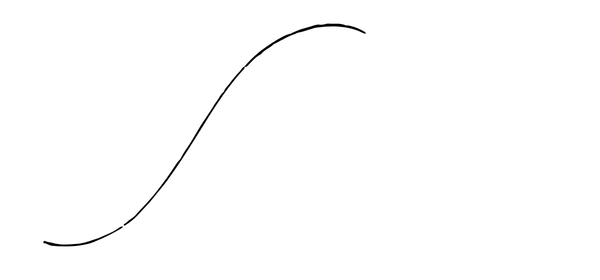

Step 4: Agent verifies data from the vessel and submits for port approval

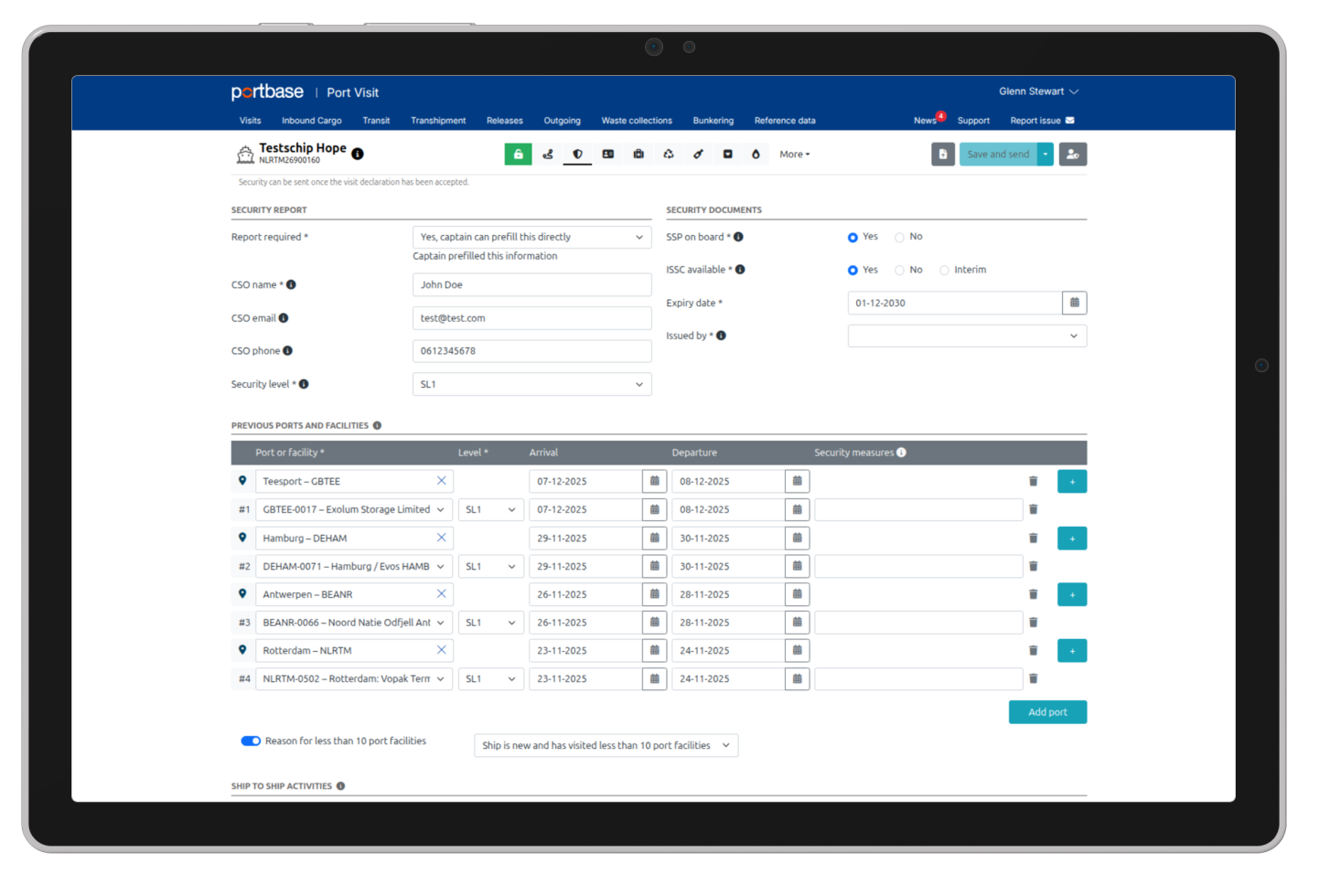

Step 3: onboard user authentication BY THE CAPTAIN

Step 2: Pre Arrival Notification triggered AT THE VESSEL

Step 1: Enabling port clearance through HARMONIZATION and global standard

CASE STUDY 5

Ship to Shore is part of the Green and Digital Corridor Programme, a large-scale international initiative that focuses on accelerating the adoption of international standards in order to achieve a more efficient and sustainable port call and enable paperless handling. About 30 chain partners participate in this programme. Ship to Shore realises a digital link between vessels and ports to make the port clearance process more efficient. Vessels have to go through this administrative process to officially gain access to a seaport. They share information about safety, cargo, crew, arrival times, and waste among other things.

Exemplary role

At Stolt Tankers, they are pleased that the ports of Rotterdam and Singapore are taking the lead in standardisation by harmonising their pre-arrival processes, aligning their data requirements and following IMO standards. ‘We hope that other ports will follow suit,’ says Sean Crowley. According to Anne Geelhoed, this also applies to CFARER. After all, the lack of standardisation also makes the development of overarching software solutions complex and time-consuming. ‘We use AI to handle this more efficiently, among other things, but that does not solve fundamental differences. Local regulations may never allow everything to be harmonised, but a large part certainly can.’

‘It shouldn't really matter which port you visit,’ says Jan-Willem den Ouden, Lead Global Data Exchange at the Port of Rotterdam Authority. ‘By using one common language with international (IMO) standards, we not only reduce the complexity and cost of integrations, but also improve port call and port planning efficiency, thanks to higher quality data coming directly from the original source: the vessel. Our aim is therefore not limited to the corridor between Rotterdam and Singapore; it is a global ambition in which we now collaborate with many ports, in close alignment with international bodies such as IAPH and BIMCO, to drive widespread adoption of these standards. By joining forces, we connect parties and get the chain moving, so that together we can achieve acceleration.’

Sustainable as well

In the Port of Singapore, port clearance information can also be shared directly with the Port Community System via an API connection. This method is faster, more secure, and less prone to errors. It is also more sustainable: mistakes in this process can force a vessel to remain at anchor or prevent it from entering the port, leading to unnecessary CO₂ emissions.

Fast, error-free, efficient

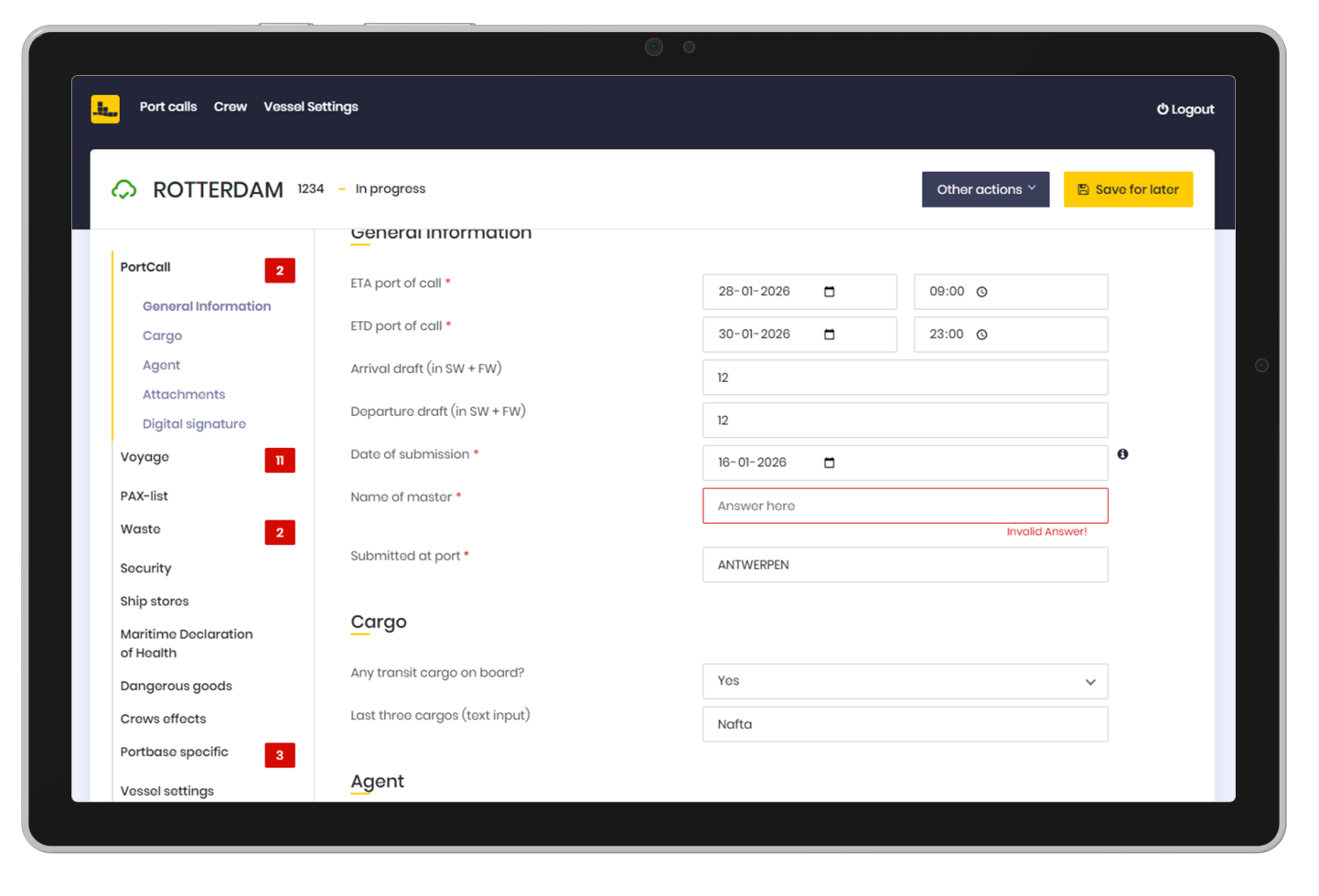

Working with Port Clearance Software also means a reduction in the burden on Sascha Boekee, Tanker Operator at Vertomcory Agencies. In Rotterdam, he reports port calls for E&S Tankers’ vessels via Portbase. He collects crew data, ISPS information, the storage list and the waste form, and processes stowage data. ‘In the past, this involved a lot of phone calls,’ says Boekee. ‘Now I receive the pre-arrival information directly from the software on board. I check that everything is correct and rectify any errors. I then share the data with Portbase via an API link. In time, captains will also be able to share information directly with Portbase, although this will never be fully complete.

Some forms may only be completed by us and, in the event of any errors, the Port of Rotterdam Authority will contact us, not the captain. Digitalisation is a huge improvement. As we already receive a lot of validated information directly in our systems, we can focus on errors and exceptions. Manual cutting, pasting, and uploading is no longer necessary, making the process faster and more efficient. I also hear a lot of positive reactions from captains: they are now a direct link in the delivery of information, which simplifies communication and prevents errors. This contributes to a smooth port call process. When an owner reports vessels that are already at anchor, we can quickly order the necessary services so that the vessel can enter the port.’

Enabling digital port clearance through global standards

ANNE GEELHOED, PRODUCT DIRECTOR, CFARER

'Setting up port clearance processes locally leads to inefficiences on board.'

SASCHA BOEKEE, TANKER OPERATOR, VERTOMCORY AGENCIES

'I also hear a lot of positive reactions from captains: they are now a direct link in the delivery of information, which simplifies communications and prevents errors.'

SEAN CROWLEY, SENIOR ELECTRICAL PROJECT MANAGER, STOLT TANKERS

'Standardisation is more than desirable. That is why we are happy to participate in this Ship to Shore pilot.'

Less administrative pressure

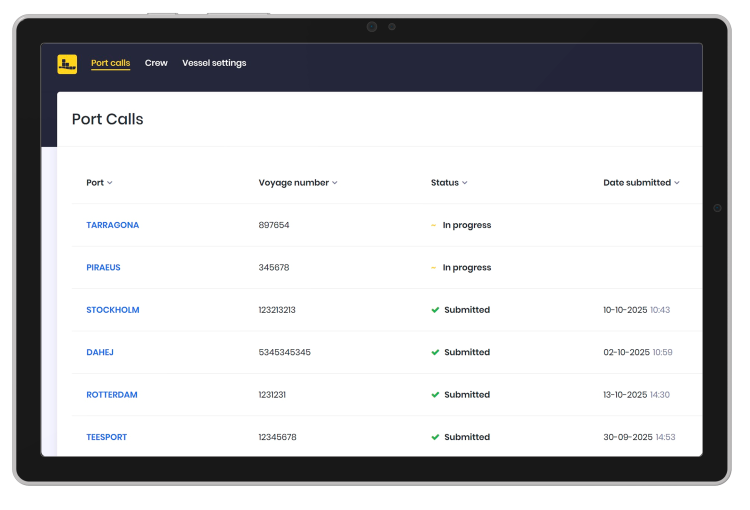

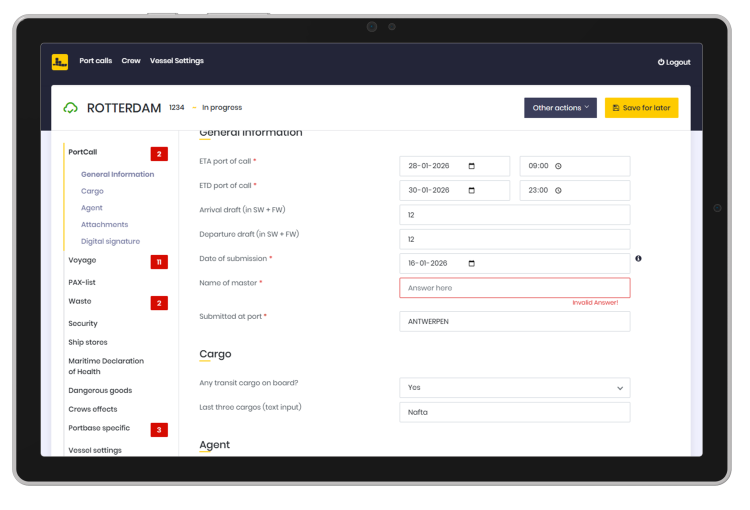

The Ship to Shore pilot focuses on far-reaching digitalisation of the port clearance process. One of the solution partners involved is CFARER, supplier of the software packages Navigator Port and Port Mate, which are installed on approximately 2,000 vessels. ‘Setting up port clearance processes locally leads to inefficiencies on board,’ says Anne Geelhoed, Product Director at CFARER.

‘Captains often spend three to four hours per port call on administrative documentation, which is at the expense of their core tasks. Our software collects the necessary data for port clearance, communicates with other systems on board, and generates the required documents for each port. Previously supplied data is reused, so captains only have to enter information once. In addition, the software automatically identifies missing information. It guides the captain step by step during the port call.’

Standardisation desired

Our vessels regularly call at the ports of Rotterdam and Singapore, and Rotterdam is also the home port of our inter-European fleet, a joint venture with Essberger Tankers (E&S Tankers).’

Per Port Call, seaports request an average of 8 to 25 documents, often with widely varying content and file formats. Where one port uses Excel or Word files, the other requires dynamic PDFs. For large, globally operating shipping companies such as Stolt Tankers, this represents a significant administrative burden. ‘We have to fill in a thousand different forms,’ says Sean Crowley, Senior Electrical Project Manager at Stolt Tankers.

The port clearance process varies greatly from seaport to seaport worldwide. Standardisation provides significant efficiency gains for shipping companies, captains, shipping agents and ports. With Ship to Shore, we bring chain parties together to increase and accelerate the adoption of this international (IMO) standards.

Scroll down

SHIP TO SHORE

TOWARDS GLOBAL STANDARDISATION WITH A DIGITAL PORT CLEARANCE

JAN-WILLEM DEN OUDEN, LEAD GLOBAL DATA EXCHANGE, PORT OF ROTTERDAM AUTHORITY

'By joining forces, we connect parties and get the chain moving so that together we can achieve acceleration.'

Our vessels regularly call at the ports of Rotterdam and Singapore, and Rotterdam is also the home port of our inter-European fleet, a joint venture with Essberger Tankers (E&S Tankers).’

SEAN CROWLEY, SENIOR ELECTRICAL PROJECT MANAGER, STOLT TANKERS

'Standardisation is more than desirable. That is why we are happy to participate in this Ship to Shore pilot.'

ANNE GEELHOED, PRODUCT DIRECTOR, CFARER

'Setting up port clearance processes locally leads to inefficiences on board.'

Step 4: Agent verifies data from the vessel and submits for port approval

Step 2: Pre Arrival Notification triggered AT THE VESSEL

Step 1: Enabling port clearance through HARMONIZATION and global standard

Step 3: onboard user authentication BY THE CAPTAIN

At Stolt Tankers, they are pleased that the ports of Rotterdam and Singapore are taking the lead in standardisation by harmonising their pre-arrival processes, aligning their data requirements and following IMO standards. ‘We hope that other ports will follow suit,’ says Sean Crowley. According to Anne Geelhoed, this also applies to CFARER. After all, the lack of standardisation also makes the development of overarching software solutions complex and time-consuming. ‘We use AI to handle this more efficiently, among other things, but that does not solve fundamental differences. Local regulations may never allow everything to be harmonised, but a large part certainly can.’

‘It shouldn't really matter which port you visit,’ says Jan-Willem den Ouden, Lead Global Data Exchange at the Port of Rotterdam Authority. ‘By using one common language with international (IMO) standards, we not only reduce the complexity and cost of integrations, but also improve port call and port planning efficiency, thanks to higher quality data coming directly from the original source: the vessel. Our aim is therefore not limited to the corridor between Rotterdam and Singapore; it is a global ambition in which we now collaborate with many ports, in close alignment with international bodies such as IAPH and BIMCO, to drive widespread adoption of these standards. By joining forces, we connect parties and get the chain moving, so that together we can achieve acceleration.’

Exemplary role

In the Port of Singapore, port clearance information can also be shared directly with the Port Community System via an API connection. This method is faster, more secure, and less prone to errors. It is also more sustainable: mistakes in this process can force a vessel to remain at anchor or prevent it from entering the port, leading to unnecessary CO₂ emissions.

Sustainable as well

SASCHA BOEKEE, TANKER OPERATOR, VERTOMCORY AGENCIES

'I also hear a lot of positive reactions from captains: they are now a direct link in the delivery of information, which simplifies communications and prevents errors.'

Working with Port Clearance Software also means a reduction in the burden on Sascha Boekee, Tanker Operator at Vertomcory Agencies. In Rotterdam, he reports port calls for E&S Tankers’ vessels via Portbase. He collects crew data, ISPS information, the storage list and the waste form, and processes stowage data. ‘In the past, this involved a lot of phone calls,’ says Boekee. ‘Now I receive the pre-arrival information directly from the software on board. I check that everything is correct and rectify any errors. I then share the data with Portbase via an API link. In time, captains will also be able to share information directly with Portbase, although this will never be fully complete.

Some forms may only be completed by us and, in the event of any errors, the Port of Rotterdam Authority will contact us, not the captain. Digitalisation is a huge improvement. As we already receive a lot of validated information directly in our systems, we can focus on errors and exceptions. Manual cutting, pasting, and uploading is no longer necessary, making the process faster and more efficient. I also hear a lot of positive reactions from captains: they are now a direct link in the delivery of information, which simplifies communication and prevents errors. This contributes to a smooth port call process. When an owner reports vessels that are already at anchor, we can quickly order the necessary services so that the vessel can enter the port.’

Fast, error-free, efficient

Ship to Shore is part of the Green and Digital Corridor Programme, a large-scale international initiative that focuses on accelerating the adoption of international standards in order to achieve a more efficient and sustainable port call and enable paperless handling. About 30 chain partners participate in this programme. Ship to Shore realises a digital link between vessels and ports to make the port clearance process more efficient. Vessels have to go through this administrative process to officially gain access to a seaport. They share information about safety, cargo, crew, arrival times, and waste among other things.

Per Port Call, seaports request an average of 8 to 25 documents, often with widely varying content and file formats. Where one port uses Excel or Word files, the other requires dynamic PDFs. For large, globally operating shipping companies such as Stolt Tankers, this represents a significant administrative burden. ‘We have to fill in a thousand different forms,’ says Sean Crowley, Senior Electrical Project Manager at Stolt Tankers.

The Ship to Shore pilot focuses on far-reaching digitalisation of the port clearance process. One of the solution partners involved is CFARER, supplier of the software packages Navigator Port and Port Mate, which are installed on approximately 2,000 vessels. ‘Setting up port clearance processes locally leads to inefficiencies on board,’ says Anne Geelhoed, Product Director at CFARER.

‘Captains often spend three to four hours per port call on administrative documentation, which is at the expense of their core tasks. Our software collects the necessary data for port clearance, communicates with other systems on board, and generates the required documents for each port. Previously supplied data is reused, so captains only have to enter information once. In addition, the software automatically identifies missing information. It guides the captain step by step during the port call.’

Less administrative pressure

Standardisation desired

CASE STUDY 5

The port clearance process varies greatly from seaport to seaport worldwide. Standardisation provides significant efficiency gains for shipping companies, captains, shipping agents and ports. With Ship to Shore, we bring chain parties together to increase and accelerate the adoption of this international (IMO) standards.