Start of

Starlings

project

Rotterdam industrial companies want to collaborate – like a flock of starlings – in the Starlings pilot project, which will be launched this year. In such a cloud of starlings, the birds move magically together, turning from left to right, up and down at the blink of an eye. For industrial plants, this pilot is looking at exchanging energy flows in a coordinated manner.

Targeted clarity

Dance class

Virtual application

Apprehensive

Nice number

‘This third step should also show whether the construction of any physical infrastructure would offer advantages. It will also clarify whether specific regulations are necessary,’ says Van der Stroom. Yokogawa has gained experience with such optimisation projects in Japan. By thinking in clusters, Kools says, it becomes clearer what infrastructure is needed. ‘It was modelled with the installation of a steam pipeline from factory A to factory F in a Japanese cluster, the entire cluster performed better as a result. That was unexpected.’ Van der Stroom acknowledges that this is new territory for the Port of Rotterdam Authority, which is investing two million euros in the project. ‘This will enable us to accelerate the energy transition. This is not the complete solution to grid congestion, but it can have a positive effect on it.’ Kools's experience is that when companies optimise separately, their primary focus is their own business operations. But the energy transition is a socio-industrial challenge, he argues. Moreover, such optimisations are not new and can even be found in practice close to home. ‘Look at Chemelot,’ he says, ‘which was originally one company – DSM – and is now disaggregated. There is indeed integrated collaboration in the field of energy, resulting in efficiency gains of up to 15 per cent.’

Source: Europoort Kringen

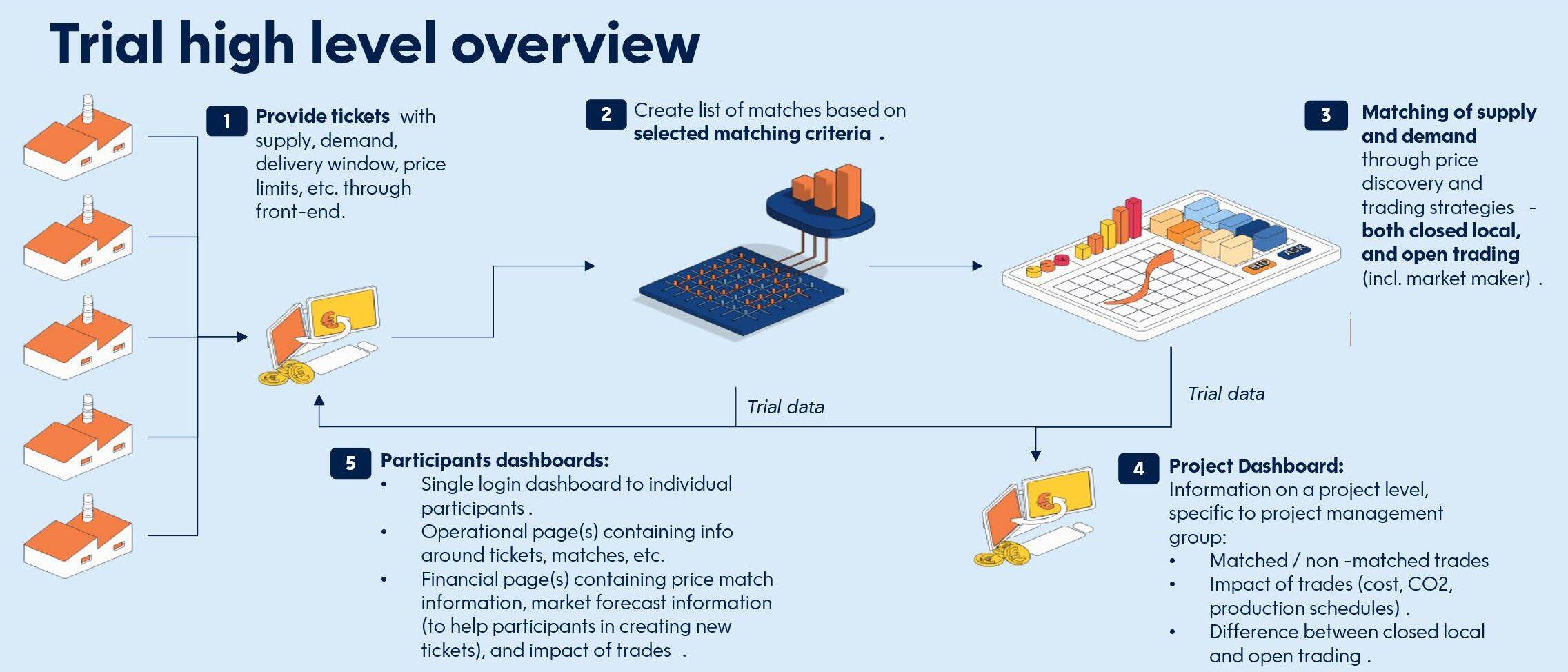

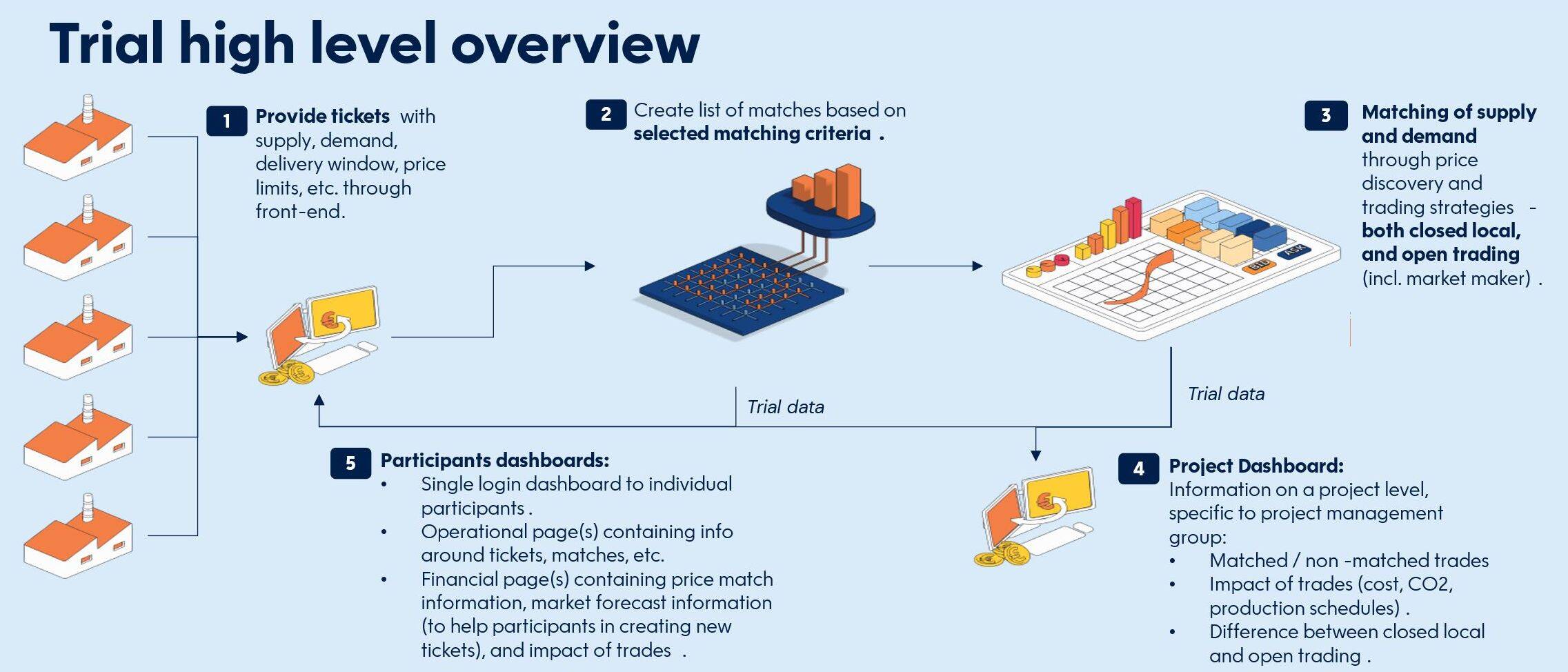

The pilot consists of three steps, which together last six months, including three months of preparation and one month of evaluation. ‘The first step is like going to dance class: you have to learn the steps,’ says Kools. ‘That should clarify whether companies are uploading the correct set of data. We use this to create a production plan that maps out the flexibility available to companies in terms of utilities. We combine this information in an intelligent pool that checks whether good matches arise. Parties for whom this is the case will receive a signal. Hopefully, this will make companies enthusiastic about the possibilities in the field of energy efficiency and CO2 reduction. We can then proceed with the third step and link this to market data with the help of our committed partner Distro Energy. We can ask the system to provide suggestions at a higher level. For example, what happens if your production shifts? We believe that the more parties get used to such coordination, the greater the gains can be.’

In the pilot, companies will theoretically apply the exchange of energy, steam, heat, electricity and CO2, Kools continues. ‘We look at the effects in terms of efficiency and emissions, not only at the companies themselves, but also across companies. What is the optimal way to operate? This is not only about saving energy, but also about promoting flexibility. It offers the opportunity to respond better to the problem of grid congestion.’ Van der Stroom believes that the challenge is not in the technology. ‘Human behaviour lies between the dream and the reality. It is not about blind faith but about reasoned trust. We have to try it. A virtual application is needed to take steps.’ Kools explains, ‘We literally sit down with companies and go through scenarios supported by technology. This should clarify what companies are up against, how this works operationally and how it fits into their business model.’

After the feasibility study, Van der Stroom and Kools held 'a validation round' at industrial companies in Rotterdam. Kools: ‘We wanted to know whether our findings were reasonable and in line with their expectations. Everyone agreed that this would generate economic gain. The follow-up question is what is needed to put this is motion. Why isn't this happening already? You then soon encounter practical barriers, such as contractual agreements or the autonomy of companies. That's something they have to deal with. It's like connecting several neighbourhood washing machines to a single solar panel system. The efficiency benefits are clear, but you have to get used to the fact that you do not decide when the laundry starts, only when it should be ready. Companies are likely to be more apprehensive rather than reluctant.’

The pilot is a follow-up to a feasibility study previously conducted by the Port of Rotterdam Authority and Yokogawa. Van der Stroom: ‘Several studies had already been conducted into how industrial clusters can save energy, but they were not practice-oriented. Our feasibility study first examined how far companies have advanced in terms of technology. We then combined existing economic studies with factory simulations, based on Yokogawa's experiences with an industrial cluster in Japan. ‘We reproduced what happens when you coordinate separate factories as one unit. That resulted in technological gains of 1.9 per cent. That is a nice number, but we also see that if you adjust the business model on a deeper level, further savings up to 5 percent come into view,’ according to Kools.

Across companies

‘Individual companies have been focusing on optimising production processes for some time now. They optimize within their own battery limits,’ says Van der Stroom. Patrick Kools, who is involved in the project as a partner from Yokogawa Electric Corporation, speaks of 'orchestration' in this context. ‘The Starlings project looks at companies as a whole by placing a layer of intelligent decision-making over them. ‘We are evaluating when it is useful to exchange what with whom, and with what effect,’ he explains. Van der Stroom adds: ‘There is integration between companies, but there is still a lack of optimisation in certain areas. They don’t always share end goals either, such as solving grid congestion or reducing CO2 emissions. The Port Authority already had a coordinating role in, for example, the construction of the hydrogen backbone and Porthos, but a new dimension in cross-border energy collaboration in the field of digitalisation was not yet available.’

Energy

Douwe van der Stroom

Douwe van der Stroom

‘It is not about blind faith but about reasoned trust’

‘The raw materials and energy transition have our attention, as does digitalisation. Within the industry, individual companies are taking steps in the field of digitalisation, but this is not yet happening from a broader perspective. This contrasts with the transport and logistics sector, where an initiative like Portbase has been running for years,’ says Douwe van der Stroom, Smart Energy and Industry Program Manager at the Port of Rotterdam Authority. The energy crisis that followed the Russian invasion of Ukraine has changed this, he notes. ‘There is increased attention to energy security and reducing energy costs. In addition, there are challenges in the area of grid congestion. This prompted the Port Authority to increase the focus on digital solutions to strengthen the resilience and business climate of the industrial cluster.’

Towards optimal cross-border collaboration

The Starlings pilot project will start in the port of Rotterdam in 2025. In the pilot, six industrial plants and two grid operators will practice the optimal exchange of electricity and utilities. That could result in cost savings up to 5 percent.

Case study 2

Scroll down

Start of

Starlings

project

The Starlings pilot project will start in the port of Rotterdam in 2025. In the pilot, six industrial plants and two grid operators will practice the optimal exchange of electricity and utilities. That could result in cost savings up to 5 percent.

Rotterdam industrial companies want to collaborate – like a flock of starlings – in the Starlings pilot project, which will be launched this year. In such a cloud of starlings, the birds move magically together, turning from left to right, up and down at the blink of an eye. For industrial plants, this pilot is looking at exchanging energy flows in a coordinated manner.

‘This third step should also show whether the construction of any physical infrastructure would offer advantages. It will also clarify whether specific regulations are necessary,’ says Van der Stroom. Yokogawa has gained experience with such optimisation projects in Japan. By thinking in clusters, Kools says, it becomes clearer what infrastructure is needed. ‘It was modelled with the installation of a steam pipeline from factory A to factory F in a Japanese cluster, the entire cluster performed better as a result. That was unexpected.’ Van der Stroom acknowledges that this is new territory for the Port of Rotterdam Authority, which is investing two million euros in the project. ‘This will enable us to accelerate the energy transition. This is not the complete solution to grid congestion, but it can have a positive effect on it.’ Kools's experience is that when companies optimise separately, their primary focus is their own business operations. But the energy transition is a socio-industrial challenge, he argues. Moreover, such optimisations are not new and can even be found in practice close to home. ‘Look at Chemelot,’ he says, ‘which was originally one company – DSM – and is now disaggregated. There is indeed integrated collaboration in the field of energy, resulting in efficiency gains of up to 15 per cent.’

Source: Europoort Kringen

Targeted clarity

The pilot consists of three steps, which together last six months, including three months of preparation and one month of evaluation. ‘The first step is like going to dance class: you have to learn the steps,’ says Kools. ‘That should clarify whether companies are uploading the correct set of data. We use this to create a production plan that maps out the flexibility available to companies in terms of utilities. We combine this information in an intelligent pool that checks whether good matches arise. Parties for whom this is the case will receive a signal. Hopefully, this will make companies enthusiastic about the possibilities in the field of energy efficiency and CO2 reduction. We can then proceed with the third step and link this to market data with the help of our committed partner Distro Energy. We can ask the system to provide suggestions at a higher level. For example, what happens if your production shifts? We believe that the more parties get used to such coordination, the greater the gains can be.’

Dance class

In the pilot, companies will theoretically apply the exchange of energy, steam, heat, electricity and CO2, Kools continues. ‘We look at the effects in terms of efficiency and emissions, not only at the companies themselves, but also across companies. What is the optimal way to operate? This is not only about saving energy, but also about promoting flexibility. It offers the opportunity to respond better to the problem of grid congestion.’ Van der Stroom believes that the challenge is not in the technology. ‘Human behaviour lies between the dream and the reality. It is not about blind faith but about reasoned trust. We have to try it. A virtual application is needed to take steps.’ Kools explains, ‘We literally sit down with companies and go through scenarios supported by technology. This should clarify what companies are up against, how this works operationally and how it fits into their business model.’

Virtual application

After the feasibility study, Van der Stroom and Kools held 'a validation round' at industrial companies in Rotterdam. Kools: ‘We wanted to know whether our findings were reasonable and in line with their expectations. Everyone agreed that this would generate economic gain. The follow-up question is what is needed to put this is motion. Why isn't this happening already? You then soon encounter practical barriers, such as contractual agreements or the autonomy of companies. That's something they have to deal with. It's like connecting several neighbourhood washing machines to a single solar panel system. The efficiency benefits are clear, but you have to get used to the fact that you do not decide when the laundry starts, only when it should be ready. Companies are likely to be more apprehensive rather than reluctant.’

Apprehensive

The pilot is a follow-up to a feasibility study previously conducted by the Port of Rotterdam Authority and Yokogawa. Van der Stroom: ‘Several studies had already been conducted into how industrial clusters can save energy, but they were not practice-oriented. Our feasibility study first examined how far companies have advanced in terms of technology. We then combined existing economic studies with factory simulations, based on Yokogawa's experiences with an industrial cluster in Japan. ‘We reproduced what happens when you coordinate separate factories as one unit. That resulted in technological gains of 1.9 per cent. That is a nice number, but we also see that if you adjust the business model on a deeper level, further savings up to 5 percent come into view,’ according to Kools.

Nice number

‘Individual companies have been focusing on optimising production processes for some time now. They optimize within their own battery limits,’ says Van der Stroom. Patrick Kools, who is involved in the project as a partner from Yokogawa Electric Corporation, speaks of 'orchestration' in this context. ‘The Starlings project looks at companies as a whole by placing a layer of intelligent decision-making over them. ‘We are evaluating when it is useful to exchange what with whom, and with what effect,’ he explains. Van der Stroom adds: ‘There is integration between companies, but there is still a lack of optimisation in certain areas. They don’t always share end goals either, such as solving grid congestion or reducing CO2 emissions. The Port Authority already had a coordinating role in, for example, the construction of the hydrogen backbone and Porthos, but a new dimension in cross-border energy collaboration in the field of digitalisation was not yet available.’

Across companies

‘It is not about blind faith but about reasoned trust’

Douwe van der Stroom

‘The raw materials and energy transition have our attention, as does digitalisation. Within the industry, individual companies are taking steps in the field of digitalisation, but this is not yet happening from a broader perspective. This contrasts with the transport and logistics sector, where an initiative like Portbase has been running for years,’ says Douwe van der Stroom, Smart Energy and Industry Program Manager at the Port of Rotterdam Authority. The energy crisis that followed the Russian invasion of Ukraine has changed this, he notes. ‘There is increased attention to energy security and reducing energy costs. In addition, there are challenges in the area of grid congestion. This prompted the Port Authority to increase the focus on digital solutions to strengthen the resilience and business climate of the industrial cluster.’

Energy

Towards optimal cross-border collaboration

Case study 2

Douwe van der Stroom