Scroll down

Case study 4

Rail Connected: Towards more transparent, efficient and resilient rail transport.

Real time

‘We are improving the efficiency and quality,’ Van Rijn continues. ‘We no longer copy PDFs into our system, with the unavoidable errors that are incurred. And of course, it doesn’t stop there. We can make more gains, such as for example predictive information about trains’ expected arrival times.’

An essential element in the digitalisation process is that we use existing interface standards. What is meant by the terms and concepts that are used? ‘You have to talk the same language. That is essential,’ Gerwin Roke, application manager at DB Cargo Nederland, explains. ‘Standards already exist for consignment notes and train data via the European Union Agency for Railways (ERA), but, for example, you see a difference between how terminals and transporters code locations in their systems. But we will figure that out along the way. There is a good atmosphere within Rail Connected. Everyone, big or small, contributes. The perspective of greater efficiency, transparency and reliability beckons.

The Cabooter Group recently joined Rail Connected as the 25th party. 'Together with APM Terminals Maasvlakte II, Combi Terminal Twente-Rotterdam, Contargo, Danser Containerline, DB Cargo Nederland, DistriRail, DP World Intermodal, ERS Railways, Hutchison Ports Europe Intermodal, Haeger & Schmidt Logistics, Hutchison Ports ECT Rotterdam, KombiRail Europe, Lineas, LTE Logistics & Transport, Neska Containerline, Optimodal, Portshuttle, Rail Force One, Raillogix, Rail Service Center Rotterdam, Rotterdam Rail Feeding, RTB Cargo, Rotterdam World Gateway and Trimodal Europe, the Rotterdam train freight sector is largely covered,' says Gilbert Bal, Business Manager Rail at Port of Rotterdam Authority.

ETA implementation

According to Smit, good progress has been made with digitalising manual operations. ‘This does not mean we are there yet though. In 2024, we want to draw up an integrated plan for how we can arrive at an optimisation of load, train paths and terminal occupation with the digitalised processes and the resulting data. That in the spirit of Nextlogic, the integrated planning system for handling inland container shipping in Rotterdam ports.’

‘We have the volume to take fundamental steps together,’ Suzanne Smits, programme manager on behalf of Port of Rotterdam Authority, states. ‘Pre-notification is up and running. Train composition is about to get started. In 2024, we are also going to address the implementation of estimated time of arrival (ETA). We have already determined how to do that, but the implementation is still creating some challenges. Traction suppliers have to add the train number in MCA Rail so that it can be linked to the ‘path’ via Railnet Europe’s Train Information System. ProRail can monitor and update the ETA via sensors in the track. This regards a so-called ‘supervised area’ of ProRail. This information is still lacking in the ‘unsupervised area’. However, ProRail is working with cameras and sensors so that those routes will also provide information. We are in discussions with them about this.’

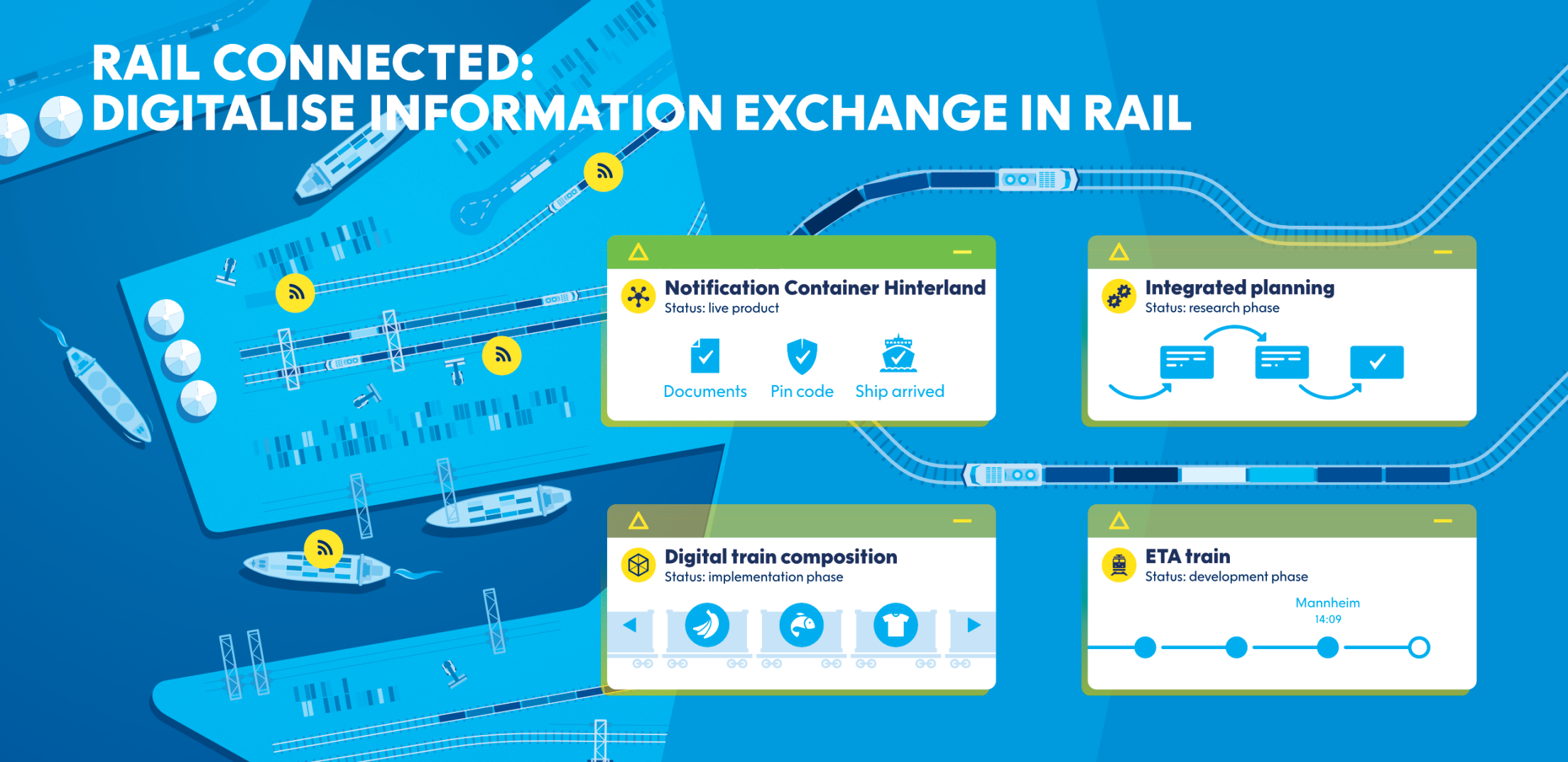

The aim is to use digitalisation to streamline the information exchange between transporters, rail operators and terminals and to reduce manual operations. The first step has been taken: pre-notification of the trains. Once a week, everyone digitally reports which trains will be running the following week. Step 2 – ‘train composition’ – the final test phase starts in January. Then there will be digital clarity about the composition of the freight trains going to and from Rotterdam in terms of locomotive, carriages and containers. In 2024 the implementation of estimated time of arrival (ETA) will also be addressed. And finally, an integrated planning system for handling container train traffic at the ports of Rotterdam is also being explored.

Momentum

These are good steps according to Rémon Kerkhof, deputy director at Optimodal, logistics service provider, which focuses on European container transport over water, rail and road. ‘Not only does this provide us, as operators, with a great deal of added value but it is also highly important for the rail sector. We have started. There is momentum, from the entire sector. It would be a shame to stop now, especially when looking at the existing growth expectations.’

Arno van Rijn concurs with that. The commercial executive of terminal operator Hutchison Ports ECT Rotterdam was already involved with Rail Connected’s predecessors: HAROLD and OnTrack. ‘At ECT, we have long been of the opinion that digitalisation is essential for the future to achieve a competitive rail supply. The previously mentioned processes were extremely ambitious. The steps we are now taking within Rail Connected are more manageable. It produces results and is relevant to all parties concerned. That’s how we get the basics in order.’

Tighter and more reliable

‘That would be a great step of course,’ Arno van Rijn from ECT comments. ‘Reliability is paramount for our clients to improve the competitive position of rail freight transport. We heartily support anything that contributes to the timely placing-in and taking-out of trains. Currently, the inefficiency in the chain effects the one party and provides flexibility and efficiency for another party. We have to move away from that. It must be tighter and more reliable. A more integrated approach can certainly help with that.’

‘Rémon Kerkhof from Optimodal also thinks that is a good solution. ‘As it stands, we have to coordinate everything one-on-one with each terminal and other party individually. That often leads to compromises which are not necessarily the best options. The system will optimise that. In itself, that should be easier to do for rail than for inland shipping. We have fewer parameters to deal with. Rail is less flexible per definition. I’m not trivialising anything by that. The startup will place great demands on everyone, but that was no different for inland shipping at Nextlogic. It is working increasingly better there now. We are going to manage that with rail too!’

The ‘Rail Connected’ growth programme stems from the Rail Freight Transport Measures Package intended to stimulate freight transport by rail. The Ministry of Infrastructure and Water Management and Port of Rotterdam Authority finance the programme. The Port of Rotterdam Authority coordinates the programme that was designed in conjunction with market parties.

Case study 4

Rail Connected: Towards more transparent, efficient and resilient rail transport.

Real time

The Cabooter Group recently joined Rail Connected as the 25th party. 'Together with APM Terminals Maasvlakte II, Combi Terminal Twente-Rotterdam, Contargo, Danser Containerline, DB Cargo Nederland, DistriRail, DP World Intermodal, ERS Railways, Hutchison Ports Europe Intermodal, Haeger & Schmidt Logistics, Hutchison Ports ECT Rotterdam, KombiRail Europe, Lineas, LTE Logistics & Transport, Neska Containerline, Optimodal, Portshuttle, Rail Force One, Raillogix, Rail Service Center Rotterdam, Rotterdam Rail Feeding, RTB Cargo, Rotterdam World Gateway and Trimodal Europe, the Rotterdam train freight sector is largely covered,' says Gilbert Bal, Business Manager Rail at Port of Rotterdam Authority.

An essential element in the digitalisation process is that we use existing interface standards. What is meant by the terms and concepts that are used? ‘You have to talk the same language. That is essential,’ Gerwin Roke, application manager at DB Cargo Nederland, explains. ‘Standards already exist for consignment notes and train data via the European Union Agency for Railways (ERA), but, for example, you see a difference between how terminals and transporters code locations in their systems. But we will figure that out along the way. There is a good atmosphere within Rail Connected. Everyone, big or small, contributes. The perspective of greater efficiency, transparency and reliability beckons.

‘We are improving the efficiency and quality,’ Van Rijn continues. ‘We no longer copy PDFs into our system, with the unavoidable errors that are incurred. And of course, it doesn’t stop there. We can make more gains, such as for example predictive information about trains’ expected arrival times.’

The aim is to use digitalisation to streamline the information exchange between transporters, rail operators and terminals and to reduce manual operations. The first step has been taken: pre-notification of the trains. Once a week, everyone digitally reports which trains will be running the following week. Step 2 – ‘train composition’ – the final test phase starts in January. Then there will be digital clarity about the composition of the freight trains going to and from Rotterdam in terms of locomotive, carriages and containers. In 2024 the implementation of estimated time of arrival (ETA) will also be addressed. And finally, an integrated planning system for handling container train traffic at the ports of Rotterdam is also being explored.

Momentum

Arno van Rijn concurs with that. The commercial executive of terminal operator Hutchison Ports ECT Rotterdam was already involved with Rail Connected’s predecessors: HAROLD and OnTrack. ‘At ECT, we have long been of the opinion that digitalisation is essential for the future to achieve a competitive rail supply. The previously mentioned processes were extremely ambitious. The steps we are now taking within Rail Connected are more manageable. It produces results and is relevant to all parties concerned. That’s how we get the basics in order.’

These are good steps according to Rémon Kerkhof, deputy director at Optimodal, logistics service provider, which focuses on European container transport over water, rail and road. ‘Not only does this provide us, as operators, with a great deal of added value but it is also highly important for the rail sector. We have started. There is momentum, from the entire sector. It would be a shame to stop now, especially when looking at the existing growth expectations.’

The ‘Rail Connected’ growth programme stems from the Rail Freight Transport Measures Package intended to stimulate freight transport by rail. The Ministry of Infrastructure and Water Management and Port of Rotterdam Authority finance the programme. The Port of Rotterdam Authority coordinates the programme that was designed in conjunction with market parties.

Tighter and more reliable

‘Rémon Kerkhof from Optimodal also thinks that is a good solution. ‘As it stands, we have to coordinate everything one-on-one with each terminal and other party individually. That often leads to compromises which are not necessarily the best options. The system will optimise that. In itself, that should be easier to do for rail than for inland shipping. We have fewer parameters to deal with. Rail is less flexible per definition. I’m not trivialising anything by that. The startup will place great demands on everyone, but that was no different for inland shipping at Nextlogic. It is working increasingly better there now. We are going to manage that with rail too!’

‘That would be a great step of course,’ Arno van Rijn from ECT comments. ‘Reliability is paramount for our clients to improve the competitive position of rail freight transport. We heartily support anything that contributes to the timely placing-in and taking-out of trains. Currently, the inefficiency in the chain effects the one party and provides flexibility and efficiency for another party. We have to move away from that. It must be tighter and more reliable. A more integrated approach can certainly help with that.’

ETA implementation

According to Smit, good progress has been made with digitalising manual operations. ‘This does not mean we are there yet though. In 2024, we want to draw up an integrated plan for how we can arrive at an optimisation of load, train paths and terminal occupation with the digitalised processes and the resulting data. That in the spirit of Nextlogic, the integrated planning system for handling inland container shipping in Rotterdam ports.’

‘We have the volume to take fundamental steps together,’ Suzanne Smits, programme manager on behalf of Port of Rotterdam Authority, states. ‘Pre-notification is up and running. Train composition is about to get started. In 2024, we are also going to address the implementation of estimated time of arrival (ETA). We have already determined how to do that, but the implementation is still creating some challenges. Traction suppliers have to add the train number in MCA Rail so that it can be linked to the ‘path’ via Railnet Europe’s Train Information System. ProRail can monitor and update the ETA via sensors in the track. This regards a so-called ‘supervised area’ of ProRail. This information is still lacking in the ‘unsupervised area’. However, ProRail is working with cameras and sensors so that those routes will also provide information. We are in discussions with them about this.’