Get in touch

Koen Vogel

Innovation Lead

Send an email

Floortje Mostert

Business Manager

Send an email

The Port of Rotterdam Authority remains committed to sustainable and efficient supply chains by validating innovation solutions together with the market. If you’re interested, contact Koen Vogel and/or Floortje Mostert or sign up for our Supply Chain Talks.

‘Success in any project is not measured solely by the completion of tasks, but by the lasting impact it creates, the challenges it overcomes. I believe that we have achieved this, considering we have managed through a digital solution to solve a critical challenge for key stakeholders in the port community to strengthen their competitiveness, and at the same time improve the flow management within our port’, adds Chawki Benouarrek, Chief Digital Officer of Tanger Med Group.

Pilot 1: Single source of truth

By sharing information via a single platform, the chain parties (shipper Driscolls, freight forwarder Puerto Transit, and customs clearance agents Partida Logistics and CSI Fresh) gained better insight into the status and accuracy of documents, allowing them to identify and correct errors early on. The shift from ‘document creation’ to ‘data entry and reuse’ resulted in error-free documentation upon arrival. This prevented over 2,500 emails to fix errors and avoided up to €300k of food freight value losses due to documentation blockages. ‘For us, the efficient processing and sharing of data has proved to be an inexhaustible source of process optimisation,’ says Ronald Hoekstra, managing director of CSI Fresh.

‘These results emphasise the critical importance of collaborative efforts within the supply chain and highlight how we, as port authorities, can lead the way through an open innovation approach’, states Koen Vogel, Innovation Lead at Port of Rotterdam Authority.

Pilot 2: Error detection with AI

Open innovation approach with market players

Both pilots have clearly demonstrated the added value of digital communication in the supply chain, especially when dealing with documents that vary from country to country. Floortje Mostert, Project Manager Digital at Port of Rotterdam Authority ‘Our experiences underline the added value of an integrated digital platform and an AI tool to detect errors. This is also valuable information for digital solution providers. The solutions tested by market parties can be quickly scaled up to other trade routes.’

Scalable

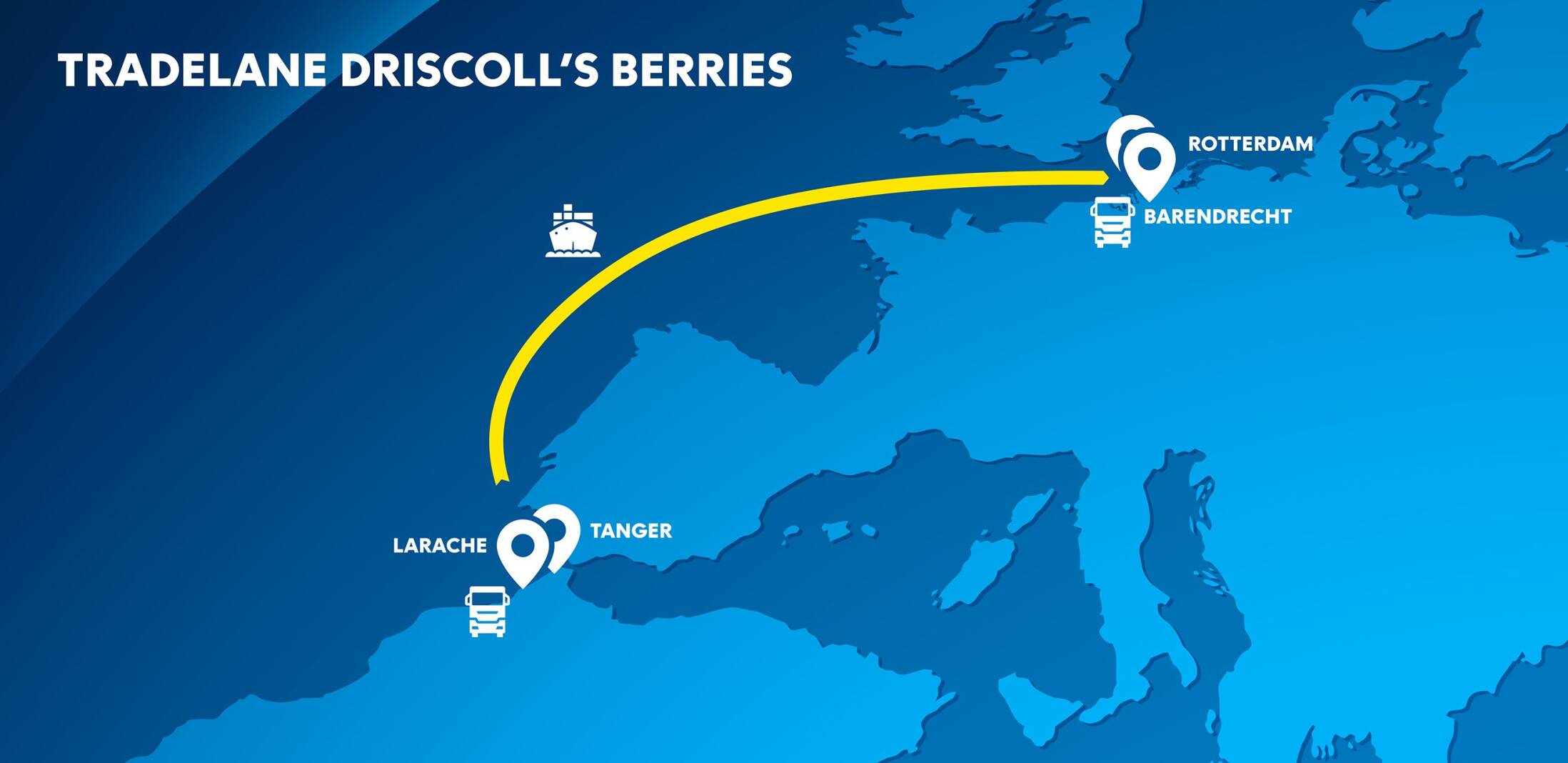

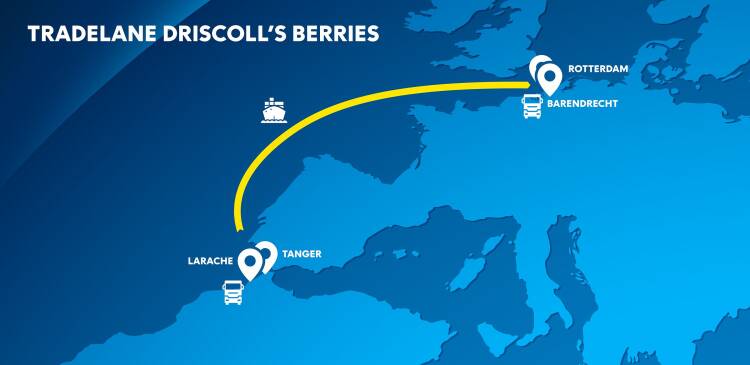

From Tanger Med, the largest African and Mediterranean container port, containers primarily carry fresh produce that needs to be transported refrigerated, such as fruit, vegetables and dairy products. Especially in this market segment, delays in container transport lead to unnecessary waste. The digitalisation of documents has a great impact on reducing food waste and enhances the efficiency of container transport.

Avoiding food waste

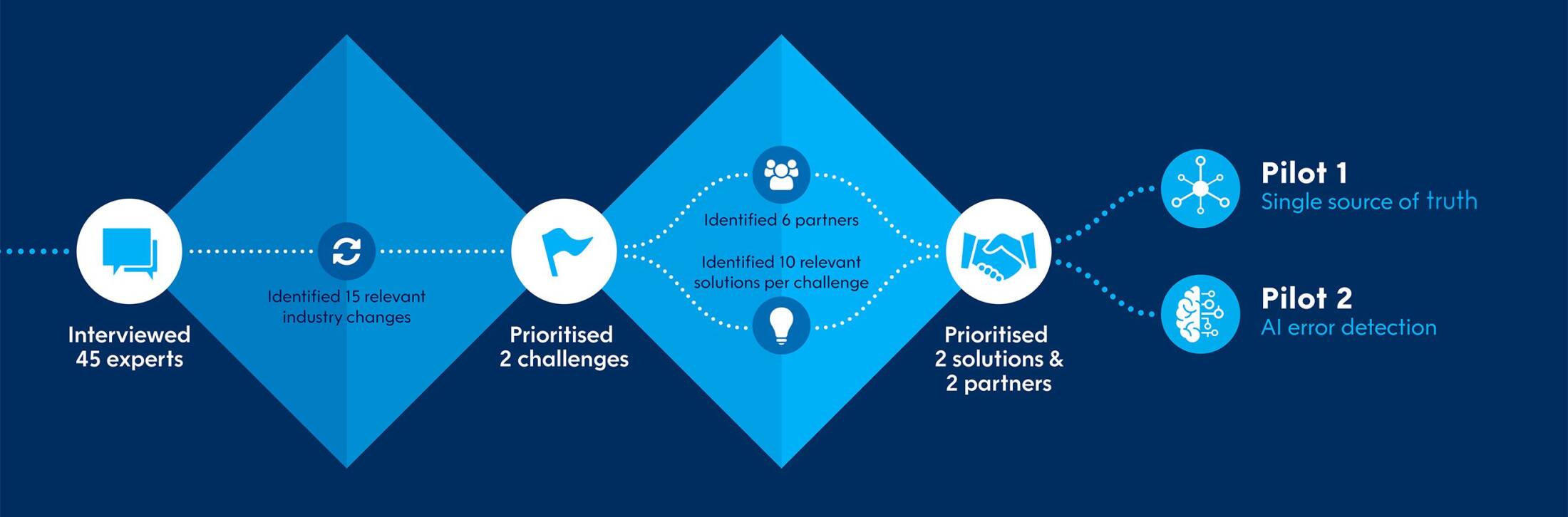

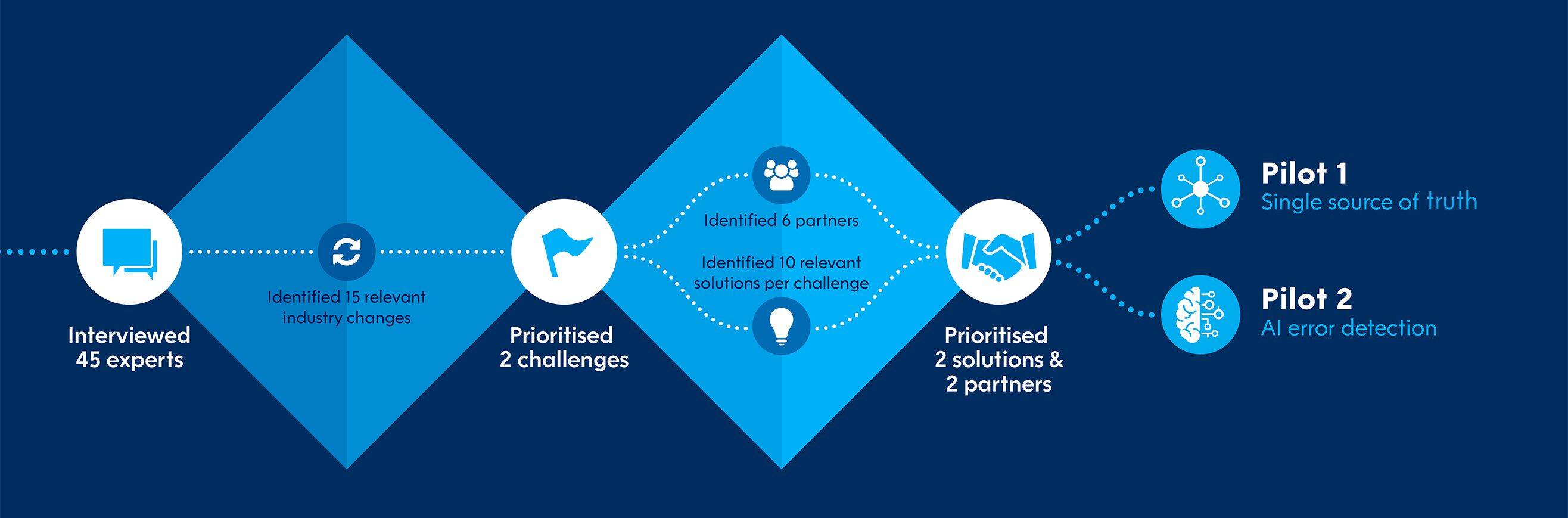

The port authorities of Rotterdam and Tanger Med have adopted an open innovation approach, working closely with various market players, port users and industry experts. This collaboration, which goes beyond traditional corporate boundaries, has resulted in a joint approach to addressing challenges identified by over 40 market players.

HI FROM THE FUTURE

Port of Rotterdam and Tanger Med (Morocco) jointly reflect on two successful pilots focused on the digitalisation of document flows in the supply chain. With proven digital solutions and involvement of market players, container shipments experience fewer delays, and food waste is avoided. Importers and exporters can apply these solutions to other trade routes, demonstrating their scalability.

We take a look at the future and where we want to be as a port. This time, we dive into the document flows between the ports of Rotterdam and Tanger Med. Read more about how this innovative approach lead to fewer delays and less food waste.

Scroll down

From paper to dataflow: error-free documents speed up container transport

One of the main priorities that emerged was reducing errors and delays in documentation processes. With these insights, the port authorities have focused on the validation of digital solutions that enable a single source of truth, making collaborative document management more efficient.

Koen Vogel

Innovation Lead

Send an email

Floortje Mostert

Business Manager

Send an email

The Port of Rotterdam Authority remains committed to sustainable and efficient supply chains by validating innovation solutions together with the market. If you’re interested, contact Koen Vogel and/or Floortje Mostert or sign up for our Supply Chain Talks.

Get in touch

Open innovation approach with market players

Both pilots have clearly demonstrated the added value of digital communication in the supply chain, especially when dealing with documents that vary from country to country. Floortje Mostert, Project Manager Digital at Port of Rotterdam Authority ‘Our experiences underline the added value of an integrated digital platform and an AI tool to detect errors. This is also valuable information for digital solution providers. The solutions tested by market parties can be quickly scaled up to other trade routes.’

Scalable

‘Success in any project is not measured solely by the completion of tasks, but by the lasting impact it creates, the challenges it overcomes. I believe that we have achieved this, considering we have managed through a digital solution to solve a critical challenge for key stakeholders in the port community to strengthen their competitiveness, and at the same time improve the flow management within our port’, adds Chawki Benouarrek, Chief Digital Officer of Tanger Med Group.

Pilot 2: Error detection with AI

By sharing information via a single platform, the chain parties (shipper Driscolls, freight forwarder Puerto Transit, and customs clearance agents Partida Logistics and CSI Fresh) gained better insight into the status and accuracy of documents, allowing them to identify and correct errors early on. The shift from ‘document creation’ to ‘data entry and reuse’ resulted in error-free documentation upon arrival. This prevented over 2,500 emails to fix errors and avoided up to €300k of food freight value losses due to documentation blockages. ‘For us, the efficient processing and sharing of data has proved to be an inexhaustible source of process optimisation,’ says Ronald Hoekstra, managing director of CSI Fresh.

‘These results emphasise the critical importance of collaborative efforts within the supply chain and highlight how we, as port authorities, can lead the way through an open innovation approach’, states Koen Vogel, Innovation Lead at Port of Rotterdam Authority.

Pilot 1: Single source of truth

From Tanger Med, the largest African and Mediterranean container port, containers primarily carry fresh produce that needs to be transported refrigerated, such as fruit, vegetables and dairy products. Especially in this market segment, delays in container transport lead to unnecessary waste. The digitalisation of documents has a great impact on reducing food waste and enhances the efficiency of container transport.

Avoiding food waste

The port authorities of Rotterdam and Tanger Med have adopted an open innovation approach, working closely with various market players, port users and industry experts. This collaboration, which goes beyond traditional corporate boundaries, has resulted in a joint approach to addressing challenges identified by over 40 market players.

Port of Rotterdam and Tanger Med (Morocco) jointly reflect on two successful pilots focused on the digitalisation of document flows in the supply chain. With proven digital solutions and involvement of market players, container shipments experience fewer delays, and food waste is avoided. Importers and exporters can apply these solutions to other trade routes, demonstrating their scalability.

Both production and import

We take a look at the future and where we want to be as a port. This time, we dive into the document flows between the ports of Rotterdam and Tanger Med. Read more about how this innovative approach lead to fewer delays and less food waste.

HI FROM THE FUTURE